High Quality for Stainless Steel Cut Wire Shot - Durable hard fiber Walnut Shells Grit – Junda

High Quality for Stainless Steel Cut Wire Shot - Durable hard fiber Walnut Shells Grit – Junda Detail:

Product Description

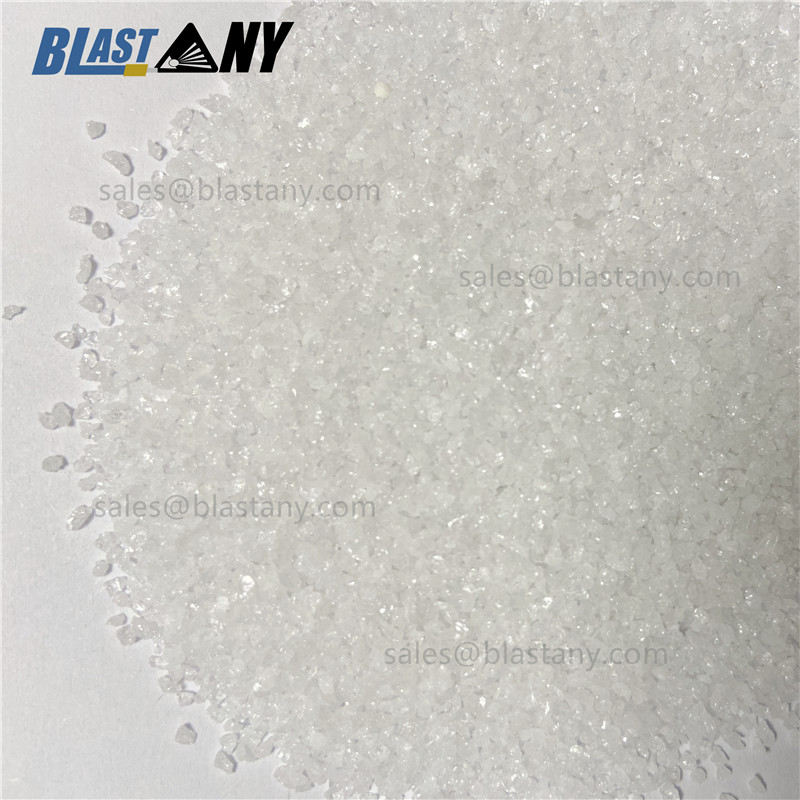

Walnut shell grit is the hard fibrous product made from ground or crushed walnut shells. When used as a blasting media, walnut shell grit is extremely durable, angular and multi-faceted, yet is considered a ‘soft abrasive’. Walnut shell blasting grit is an excellent replacement for sand (free silica) to avoid inhalation health concerns.

Cleaning by walnut shell blasting is particularly effective where the surface of the substrate under its coat of paint, dirt, grease, scale, carbon, etc. should remain unchanged or otherwise unimpaired. Walnut shell grit can be used as a soft aggregate in removing foreign matter or coatings from surfaces without etching, scratching or marring cleaned areas.

When used with the right walnut shell blasting equipment, common blast cleaning applications include stripping auto and truck panels, cleaning delicate molds, jewelry polishing, armatures and electric motors prior to rewinding, deflashing plastics and watch polishing. When used as a blast cleaning media, walnut shell grit removes paint, flash, burrs and other flaws in plastic and rubber molding, aluminum and zinc die-casting and electronics industries. Walnut shell can replace sand in paint removal, graffiti removal and general cleaning in restoration of buildings, bridges and outdoor statuaries. Walnut shell is also used to clean aircraft engines and steam turbines.

Technical Parameters

|

Walnut Shell Grit Specifications |

|

|

Grade |

Mesh |

|

Extra Coarse |

4/6 (4.75-3.35 mm) |

|

Coarse |

6/10 (3.35-2.00 mm) |

|

8/12 (2.36-1.70 mm) |

|

|

Medium |

12/20 (1.70-0.85 mm) |

|

14/30 (1.40-0.56 mm) |

|

|

Fine |

18/40 (1.00-0.42 mm) |

|

20/30 (0.85-0.56 mm) |

|

|

20/40 (0.85-0.42 mm) |

|

|

Extra Fine |

35/60 (0.50-0.25 mm) |

|

40/60 (0.42-0.25 mm) |

|

|

Flour |

40/100 (425-150 micron) |

|

60/100 (250-150 micron) |

|

|

60/200 (250-75 micron) |

|

|

-100 (150 micron and finer) |

|

|

-200 (75 micron and finer) |

|

|

-325 (35 micron and finer) |

|

| Product name | Proximate Analysis | Typical Properties | ||||||||

| Walnut Shell Grit | Cellulose | Lignin | Methoxyl | Nitrogen | Chlorine | Cutin | Toluene Solubility | Ash | Specific Gravity | 1.2 to 1.4 |

| 40 – 60% | 20 – 30% | 6.5% | 0.1% | 0.1% | 1.0% | 0.5 – 1.0 % | 1.5% | Bulk Density (lbs per ft3) | 40 – 50 | |

| Mohs Scale | 4.5 – 5 | |||||||||

| Free Moisure (80ºC for 15 hrs) | 3 – 9% | |||||||||

| pH (in water) | 4-6 | |||||||||

| Flash Point (closed cup) | 380º | |||||||||

Product detail pictures:

Related Product Guide:

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for High Quality for Stainless Steel Cut Wire Shot - Durable hard fiber Walnut Shells Grit – Junda , The product will supply to all over the world, such as: Qatar, Costa Rica, Danish, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Products categories