Koc approvl Garnet sand for Perfect Surface Treatment

Junda Advantages in Waterjet Cutting

Garnet comes in two basic forms, crushed and alluvial, the later being roughly similar to sand washed up on riversides. Our garnet for export is produced from our crystalline almandite garnet and river garnet sand. deposits. Thank to its sharp edges from crushing, this kind crushed garnet acts more like a sharp cutting tools so that it is superior to alluvial and have been shown to cut better and faster.

Sharper Edges

Due to our Junda garnet sandis crushed from almandine rock, it acts more like a sharp cutting tools and can cut faster and more efficiently than alluvial garnet.

Faster Cutting

Crushed and selected from hard rock so that Junda waterjet grade garnet produces harder and sharper edges than other waterjet abrasives. These characteristics enable our garnet more like a hard and sharp cutting tool to finish a faster cutting.

Better Edge quality

According to the cutting material and edge quality requirement, there are various special and proper waterjet grades recommended that enable a better edge quality.

Less Dusty

Junda garnet has high garnet purity and very low dust. That makes the whole cutting course more smoothly.

Sea Garnet

River Garnet

Rock Garnet Sand

Choosing the Proper Mesh or Grade

Junda offers various grades to match any focusing tube and orifice for any given cutting applications. Choosing the proper mesh, or grade, for the operation is very imperative. Different mesh sizes of garnet are designed to pass through different sized nozzles and choosing the wrong grade could be stop a waterjet operation completely. If the garnet grade is too large or coarse, the granules can jam inside a tube and cause a blockage. Too fine an abrasive have a tendency to “clump” together inside the cutting head and again, have the potential to clog. Or it may inhibit the flow of garnet in the feed tube and not consistently enter the venture of water flow between the jewel and nozzle. If you are not sure which mesh or grade is proper, feel free to contact us and we would like to give you our professional suggestions.

| Coarse | 60 Mesh |

| Medium | 80 Mesh |

| Fine | 120 Mesh |

| More fine grades | 150 mesh, 180 mesh, 200 mesh, 220 mesh |

Average Chemical Composition (Typical)

| Al2O3 | 18.06% |

| Fe2 O3 | 29.5% |

| Si O2 | 37.77% |

| MgO |

4.75% |

| CaO | 9% |

| Ti O2 | 1.0% |

| P2 O5 | 0.05% |

| Mn O | 0.5% |

| Zr O2 | Traces |

| CHLORIDE CONTENT | Less than 25ppm |

| SOLUBLE SALTS | Less than 100 ppm |

| PH OF AQUEOUS MEDIUM | 6.93 |

| GYPSUM CONTENT | Nil |

| MOISTURE CONTENT | Less than 0.5% |

| CARBONATE CONTENT | Traces |

| LOSS ON IGNITION | Nil |

| METAL CONTENT | Traces |

Other Characteristics

| Crystal System | Cubic |

| Habit | Trapezohedron |

| Fracture | Sub-Conchoidal |

| Durability | Very good |

| Free Flow | 90% Minimum |

| Susceptibility to Acid | None |

| Moisture Absorption | Non Hygroscopic, Inert. |

| Magnetism | Very Slightly Magnetic |

| Conductivity | Less than 25 Microsiemens per Meter |

| Radio Activity | Not Detectable above background |

| Pathological Effects | None |

| Free Silica Content | None |

Mineralogical Composition

|

Garnet (Almandite) |

97-98% |

|

Ilmenite |

1-2% |

|

Quartz |

<0.5% |

|

Others |

0.5% |

Physical Characteristics

| Specific Weight | 4.1 g/cm3 |

| Average Bulk | 2.4 g/cm3 |

| Hardness | 7 (Mohs Scale) |

| Mesh | Size MM | 16/30 MESH | 20/40 MESH | 20/60 MESH | 30/60 MESH | 40/60 MESH | 80 MESH |

| 14 | 1.40 | ||||||

| 16 | 1.18 | 0-5 | 0-1 | ||||

| 18 | 1.00 | 10-20 | |||||

| 20 | 0.85 | 20-35 | 0-5 | 0-5 | 0-1 | ||

| 30 | 0.60 | 20-35 | 30-60 | 10-25 | 0-10 | 0-5 | |

| 40 | 0.43 | 0-12 | 35-60 | 25-50 | 10-45 | 40-65 | 0-5 |

| 50 | 0.30 | 0-18 | 25-45 | 40-70 | 30-50 | 0-50 | |

| 60 | 0.25 | 0-5 | 0-15 | 5-20 | 10-20 | 15-50 | |

| 70 | 0.21 | 0-10 | 0-7 | 10-55 | |||

| 80 | 0.18 | 0-5 | 0-5 | 5-40 | |||

| 90 | 0.16 | 0-15 |

Application

Sandblasting

Garnet sand abrasive has features of good hardness, high bulk density, heavy specific weight, good toughness and no free silica. It is widely used in aluminum profile, copper profile, precision molds, and many other fields. And it is used for sandblasting, rust removing and surface treatment in stainless steel, carbon steel, steel structure, aluminum, titanium, galvanized parts, glass, stone, wood, rubber, bridge, shipbuilding, ship repair, etc.

Water Filtration

Thanks to it heavy specific weight and stable chemical properties. Our garnet sand 20/40# can be used as the bottom media of filter bed in water filtration of chemical industry, petroleum, pharmacy, cleaning drinking water or waste. It is one of the most cost effective alternatives for water filtration beds to replace silica sand and gravel in water filtration, Especially it can be applied in beneficiation of non-ferrous metals and oil drilling mud weighting agent, because it resets the filter bed more rapidly after the filter bed is back-flushed.

Water Jet Cutting

Our garnet sand 80# has features of sub conchoidal fracture, high hardness, good toughness and sharp edges.It can form new angular edges constantly during crushing and classifying. Water jet cutting uses garnet sand as the cutting medium, relies on high-pressure water jets to water jet cut oil and gas pipelines, steel and other components, stainless steel, copper, metal, marble, stone, rubber, glass, ceramics. Also for its high speed and fluency in water jet cutting, it will not jam the cutting tool bit used on water jet cutting machine.

Customer

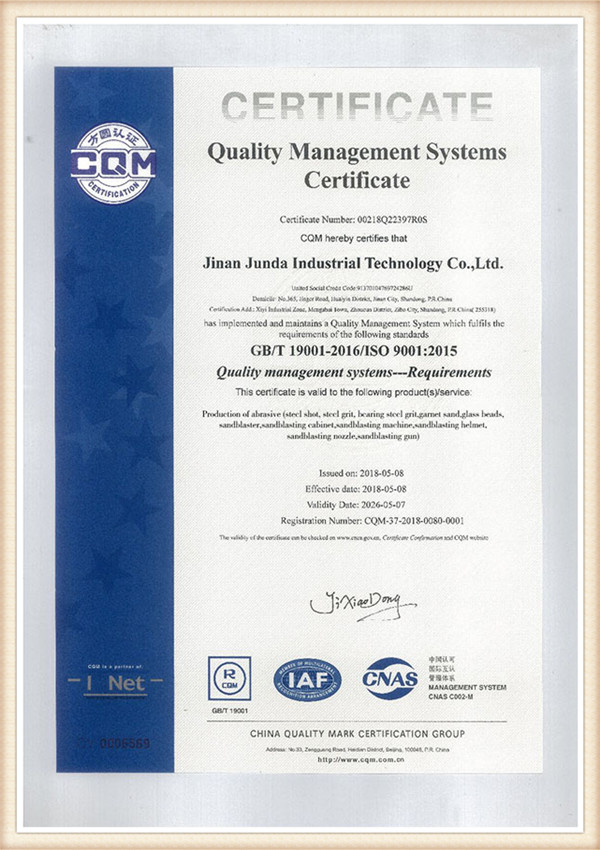

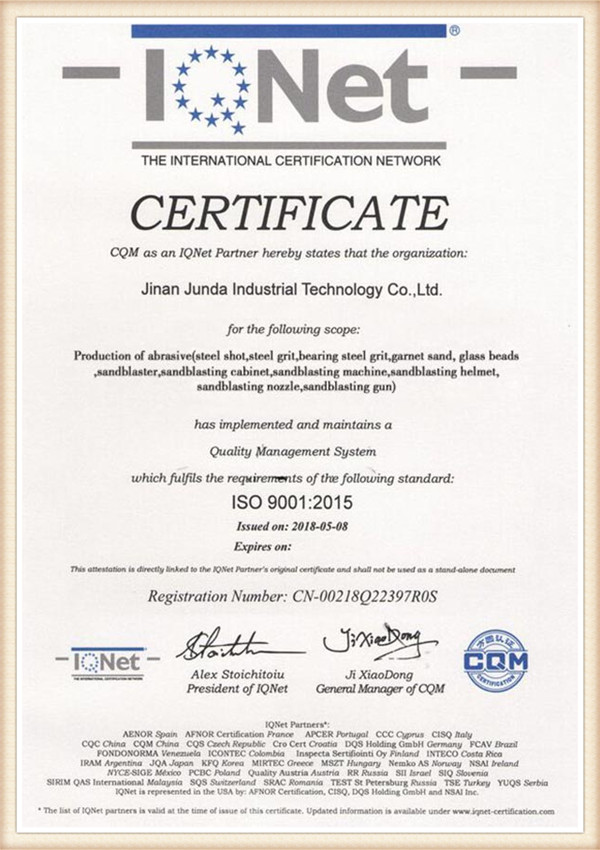

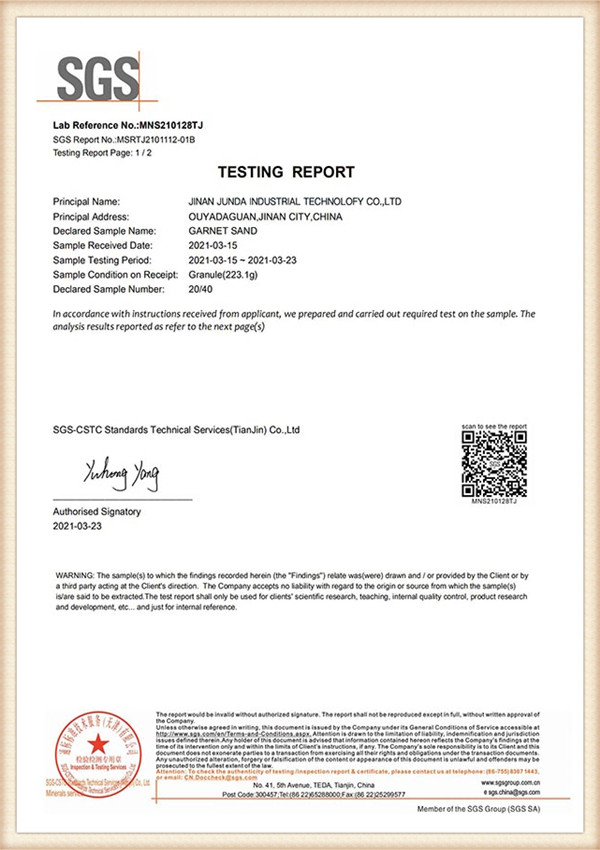

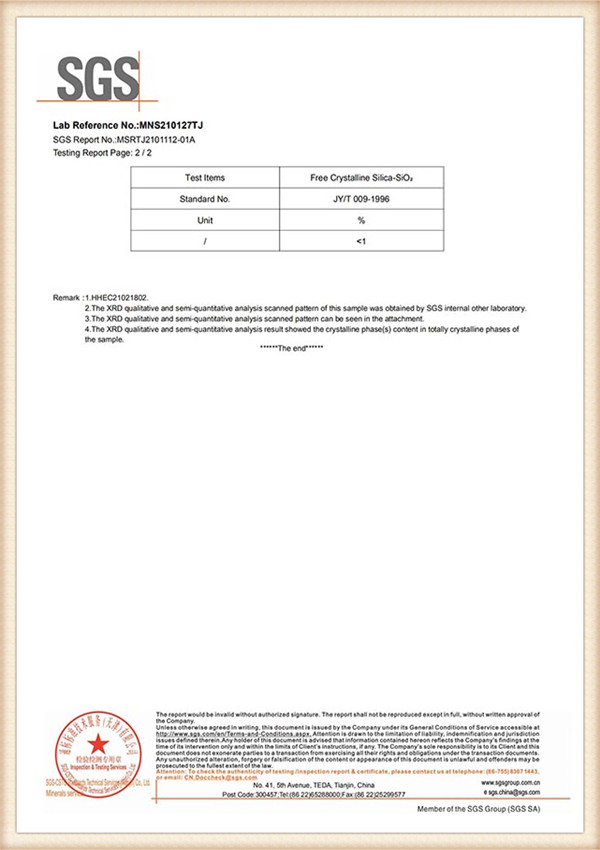

Certificate

Products categories