Sandblasting Gun

-

Wireless charging handheld electric portable nano Blue light disinfection spray gun

Features: 100% brand new and high quality. High-quality nanos spray port, using PA high temperature resistant material, fast fogging, large amount of fog With 540ml large capacity water tank, longer use time.Made of quality plastic material, durable to use. The compact body allows you to feel comfortable with the ergonomic design of the handle anywhere, Easy

to carry, can be used in homes and beauty salons. Can put the disinfectant in a volumetric flask, can also be used for disinfection and sterilization, safe and effective. -

Sand Blasting Machine for Steel Pipe Inner JD SG4 /Internal Wall Surface Rust Scale Cleaning

JD SG4 series pipeline inwall sandblaster is a special device supporting the use of sandblasting machine to clean the pipeline inwall. It can be used in manual work, also in automatic work if equipped with other devices. These series are suitable for the pre-treatment of coating pipeline inwall in the fields of oil, chemical industry and shipping. The degree of surface quality after the treatment is up to Sa2 and Sa3. These sandblasters can handle the pipelines whose ID ranges from φ60mm to φ800mm. They are convenient and safe to use and maintain easily.

-

High pressure sandblasting gun JD-SG-2

All in one – pressure washer sandblasting attachments have a goggle, 10 feet hose, 16 inch pressure water input washer wand, 17 inch sand input sand wand, two hose clamps and extra replacement ceramic nozzle kit.

Durable – Made of durable material, brass and stainless steel, Max working pressure of sandblaster attachment is 5000 PSI, temperature is up to 140F, and replacment Nozzles are available. -

JDSG-3

Product Presentation High quality kit tackles any job around the shop or home; complete with quick connector, extra steel tip, media filter, user manual & media guide High performance tool designed to outperform with gravity fed reservoir to ensure more consistent work; fully adjustable control valve that automates sand flow precisely Versatile to use; supports media such as steel grit, glass beads, silicon carbide and more; cleans, restores, and prevents corrosion on multiple surfaces;... -

JDSG-4-1 Sand Blasting Machine for Steel Pipe Inner/Internal Wall Surface Rust Scale Cleaning

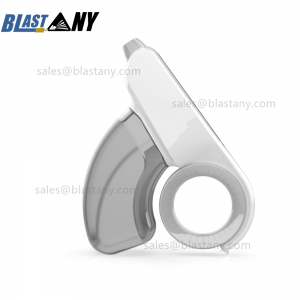

Compact and lightweight sandblasting gun JDSG-1

-

Jdsg-4-4 Steel tube inner wall sand blasting machine 360 degree rotation sand blasting

Suitable for all kinds of sandblasting cabinet sandblasting gun JDSG-5

-

Siphon blasteing gun Junda-HG-1

Sandblaster Abrasive Sand Blasting Gun Air Siphon Feed Blast Gun Dust Collector with Jet Fast Adapter For Sand Blasting Cabinet VS0001104 Can be used for sand glass, sandblasting, surface polishing processing, machinery parts, such as surface cleaning, rust removal and glass, aluminum alloy and other decorative surface sandblasting, marble engraving.

-

Sandblasting Gun With Aluminum Alloy Type A、 type B and type C

Junda has been specialized in the sand blasting gun production and development of boron carbide, silicon carbide and tungsten carbide for many years. Sandblast Gun, designed for fast efficient sand blasting, liquid or air cleaning of parts and surfaces, is a king of powerful tool for removing tar, rust, old paint and many other materials. It’s also widely used in the making of frosted glass in the factory. The composition of the liner material determines its wear resistance. It can be stainless steel and Aluminum. There are also boron carbide, silicon carbide and tungsten carbide nozzles inserts installed in the blast gun. The taper and length of the nozzle’s inlet and outlet determine the pattern and velocity of the abrasive exiting the nozzle.