High quality steel slag 60-80Mesh for good rust removal effect

Production process

The steel slag processing process is for the sake of separating different elements from the slag. It involves the process of separation, crushing, screening, magnetic separation, and air separation of the slag generated during the steel smelting process. The iron, silicon, aluminum, magnesium, and other elements contained in the slag are separated, processed, and reused to greatly reduce environmental pollution and achieve effective utilization of resources.

Product parameter

|

Junda Steel slag |

||||||||

|

Model |

Leading indicator |

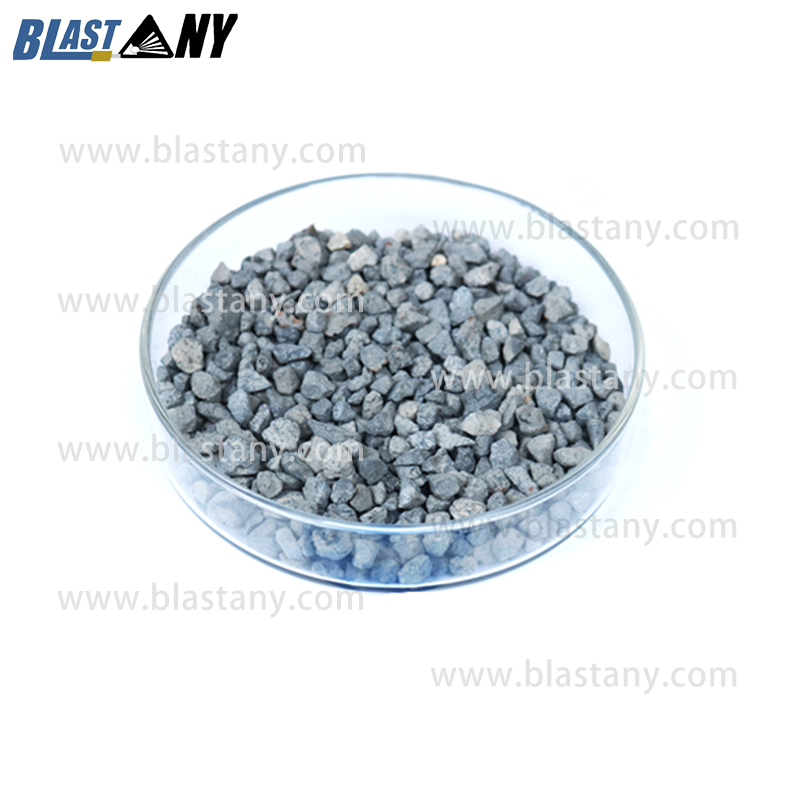

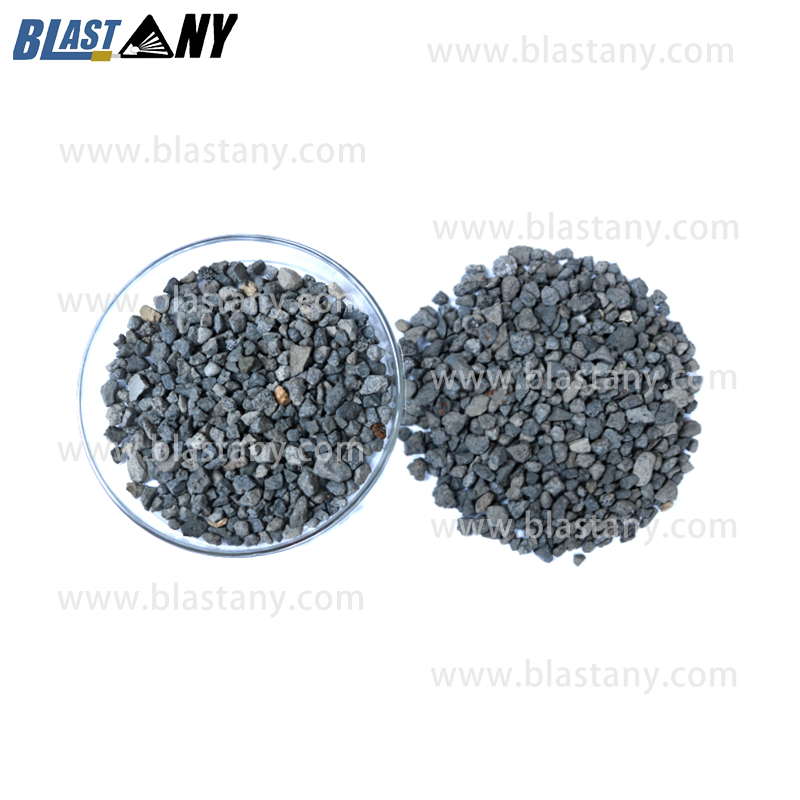

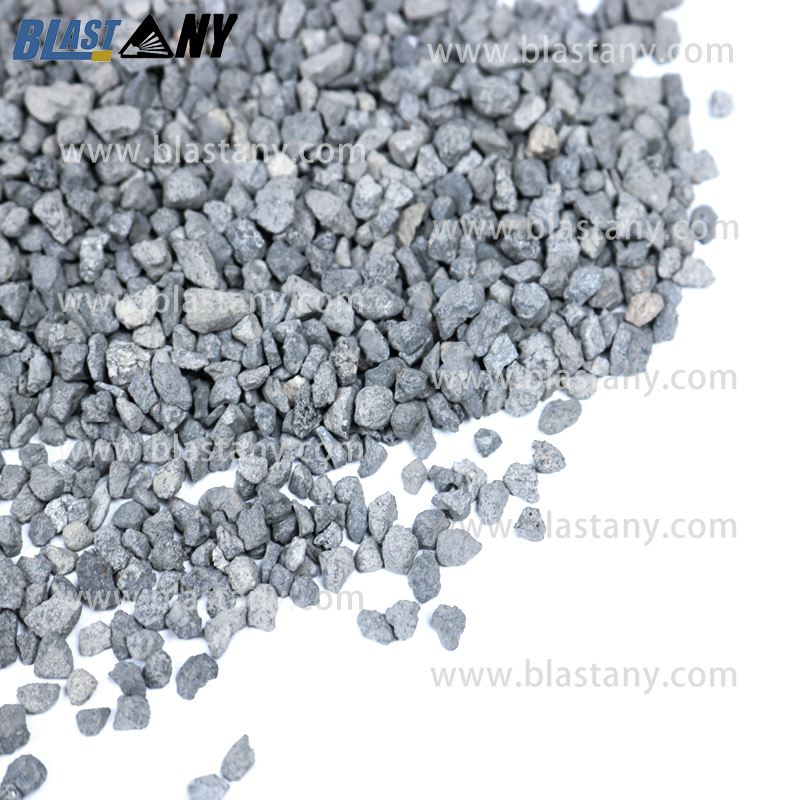

Color |

Shape |

Hardness(mohs) |

Bulk density |

Application |

Moisture content |

SIZE |

|

Steel slag |

TFe |

gray |

Angular |

7 |

2tons/m3 |

Sandblasting |

0.1%MAX |

6-10Mesh 10-20Mesh 20-40Mesh 40-80Mesh |

|

15-20% |

||||||||

Advantages

Large quantity, waste utilization.

Environmental protection and safety, harmless to the human body.

Sharp edges, good rust removal effect.

Moderate hardness, low loss rate.

Application

Manufacturing and quality management of iron and steel slag products have a broad range of applications. As a result, iron and steel slag products are playing a vital role as building materials for construction materials for infrastructure such as, ports, airports across the globe, as well as eco-friendly materials for restoring and improving the marines and soils.

Products categories