Garnet sand inertness, high melting point, good toughness, insoluble in water, solubility in acid is only 1%, basically does not contain free silicon, has a high resistance to physical impact performance; Its high hardness, edge sharpness, grinding force and specific gravity, together with its recycling ability, make it an ideal multi-purpose material for many industrial sectors; Garnet can be used as a percolating medium to water jet cutting, sandblasting, etc. At present, it has been used in many important industrial sectors, such as optical industry, electronic industry, machinery industry, instrumentation, printing industry, building materials, as well as mining and other sectors;

Red garnet is broken by natural ore processing, the production process is energy-saving, there is no high energy consumption process. Due to its own particle shape and self-sharpness, its sandblasting efficiency is high, the recovery rate is high, is an economic cost-effective abrasive. Red garnet sandblasting grade is high, can be able to deep holes and uneven parts to clean up, completely remove the oxide layer, rust, residual salt, burrs and other debris, sandblasted surface without embeddings, no adverse convex tip and pit, no sand, to achieve SA3 sandblasting grade, uniform surface roughness. The surface roughness can reach 45-55, 50-75 microns. The surface roughness after sandblasting is moderate, and the adhesion between the coating (coating, adhesive parts) is good,garnet sand abrasive has features of good hardness, high bulk density, heavy specific weight, good toughness and no free silica. It is widely used in aluminum profile, copper profile, precision molds, and many other fields.

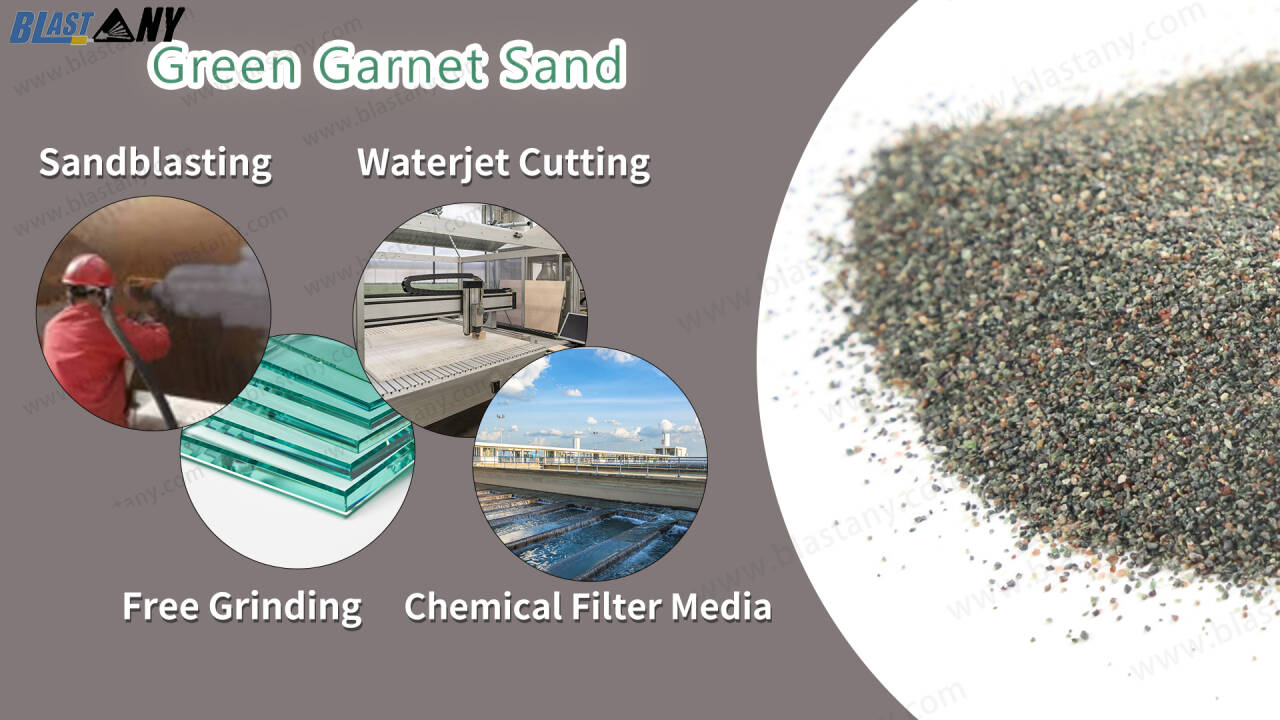

Omphacite abrasive, also known as green garnet blasting abrasive, is a general purpose blasting abrasive consisting of a totally naturally occuring blend of almandine green garnet and almandine red garnet.

This natural blend offers fast cleaning of the surface while still producing a surface profile around 70 microns and is suitable for use on most materials from bare steel to mid – level coated surfaces.Moderate abrasive hardness, high packing density, no free silica, greater than major, good toughness, is an ideal "environmental protection" type sandblasting material, widely used in aluminum, copper, glass, washed jeans. Precision mold and other fields

Red garnet abrasive blasting advantages:

1. Garnet has stable physical and chemical properties, significant, high hardness (Mohs hardness is 7.5-8), and the particles have bright edges and corners, making the sandblasting rust removal efficiency is high

2. Garnet self-sharpening is good, in the sand blasting crushing process, constantly produce new edges and corners, can be reused 2-3 times.

3. The content of free silicon in garnet is small, which avoids silicosis and does not affect the health of sandblasting workers.

4. The garnet production process is pure physical processing, such as crushing, washing, magnetic separation, and no chemical agents are added in the production process, which will not have adverse effects on production workers and the local environment

Benefits of blasting with green garnet abrasive including,

Mosh hardness of 7.5

Environmentally and health-safe (contains no heavy metals)Vitually silica free (less than 0.5%)

Reduce air emissions greatly with green garnet abrasive

Low chlorides, low soluble salts (less than 7ppm)

With proper metering, 70% less abrasive is used than slag & cuts 30-40% faster than slag, Unique grain hardness / toughness reduces particle breakdown

Bulk density of 150lbs / ft3 vs. 110lbs. for sand & slag abrasives

Recycles 3-6 times depending on the application, Lower abrasive disposal cost / no containment cost

Post time: Feb-25-2025