Welcome to our websites!

News

-

Garnet’s Advantages in Replacing Quartz Sand

1. Sandblasting,Rust Removal & Surface Treatment - Reasons for Substitution: - Environmental Protection: Quartz sand contains free silica, which can easily generate dust pollution during sandblasting. Long-term inhalation may cause silicosis. Garnet sand does not contain free silica, meeting ...Read more -

Sand blaster: SB10 vs 28-gallon with Vacuum recycler

Our Sandblasting machine is widely used in ship building, mining, machinery, oil pipelines, machine tools, metallurgy, boiler,machinery manufacturing, port construction, water conservancy projects such as surface derusting, smooth surface.It is the most widely used product of abrasive jet, and th...Read more -

Garnet Sand: Striking the Optimal Balance Between Cutting Performance and Cleanliness

Garnet sand is widely used as an abrasive in waterjet cutting due to its high hardness, sharp edges, and environmental friendliness. However, in practical applications, achieving the optimal balance between its cutting efficiency and system cleanliness is crucial for maximizing overall benefits. ...Read more -

Garnet sand selection & Production cost

Garnet Abrasives: Market Dynamics Driven by Demand and Cost Due to its core advantages of low dust and recyclability, garnet abrasives have seen a continued increase in sandblasting, water treatment and other fields in recent years. Demand: A Structural Upgrade from “Substitution” to...Read more -

Why Glass Beads Surface-Friendly Than Other Abrasives?

Glass beads exhibit greater “surface-friendliness” compared to numerous other abrasives, such as alumina, silicon carbide, and steel grit. This characteristic is primarily attributed to its distinct physical and chemical properties. The surface-friendliness of glass beads is manifeste...Read more -

Different standard of the surface cleanness technology

Surface cleanness is very important for the work pieces or metal parts before coating and painting . Usually, there is no single, universal cleanliness standard and it depends on the application. However, there are indeed some general guidelines include visual cleanliness (no visible dirt, dust,...Read more -

Dry sandblasting vs Wet sandblasting vs Vacuum sandblasting

Sandblasting for rust removal is one of the high-quality surface pre-treatment methods. It not only can completely remove the oxide scale, rust, old paint film, oil stains and other impurities from the metal surface, making the metal surface show a uniform metallic color, but also can give the me...Read more -

The Ultimate Revelation of the Effects of Non-metallic Abrasives in Different Sandblasting Scenarios

Non-metallic abrasives are widely used in various sandblasting scenarios, with significant differences in effects. The key considerations for choosing non-metallic abrasives are as follows: 1.Material of the substrate: Different materials have different requirements for the hardness and cutting ...Read more -

Application of traditional sandblasting abrasives in the new energy industry

As we all know, traditional sandblasting abrasives have a wide range of applications across various industries. Today, we will focus on their applications in the New Energy Industry. Traditional sandblasting abrasives are primarily used in the new energy industry for material surface pretreatment...Read more -

Application of Abrasives in Automobile Manufacturing: Selection and Quality Improvement

In the field of automobile manufacturing, the rational selection of blasting abrasives plays a crucial role in improving the surface treatment quality of automobile parts. Different types of abrasives have their own unique properties and are suitable for different stages of automobile manufacturi...Read more -

The Advantages of Chrome Steel Shot &Grit-Our Patented Product

1.introduction: We produce two types of steel shots&grit. Standard Steel Shot/Grit & Chrome Steel Shot/Grit. The Chrome Type contains Cr element 0.2-0.4% has longer fatigue life, reaching up to 2600-2800 times. By adding certain Chrome element in the production, it makes the steel good te...Read more -

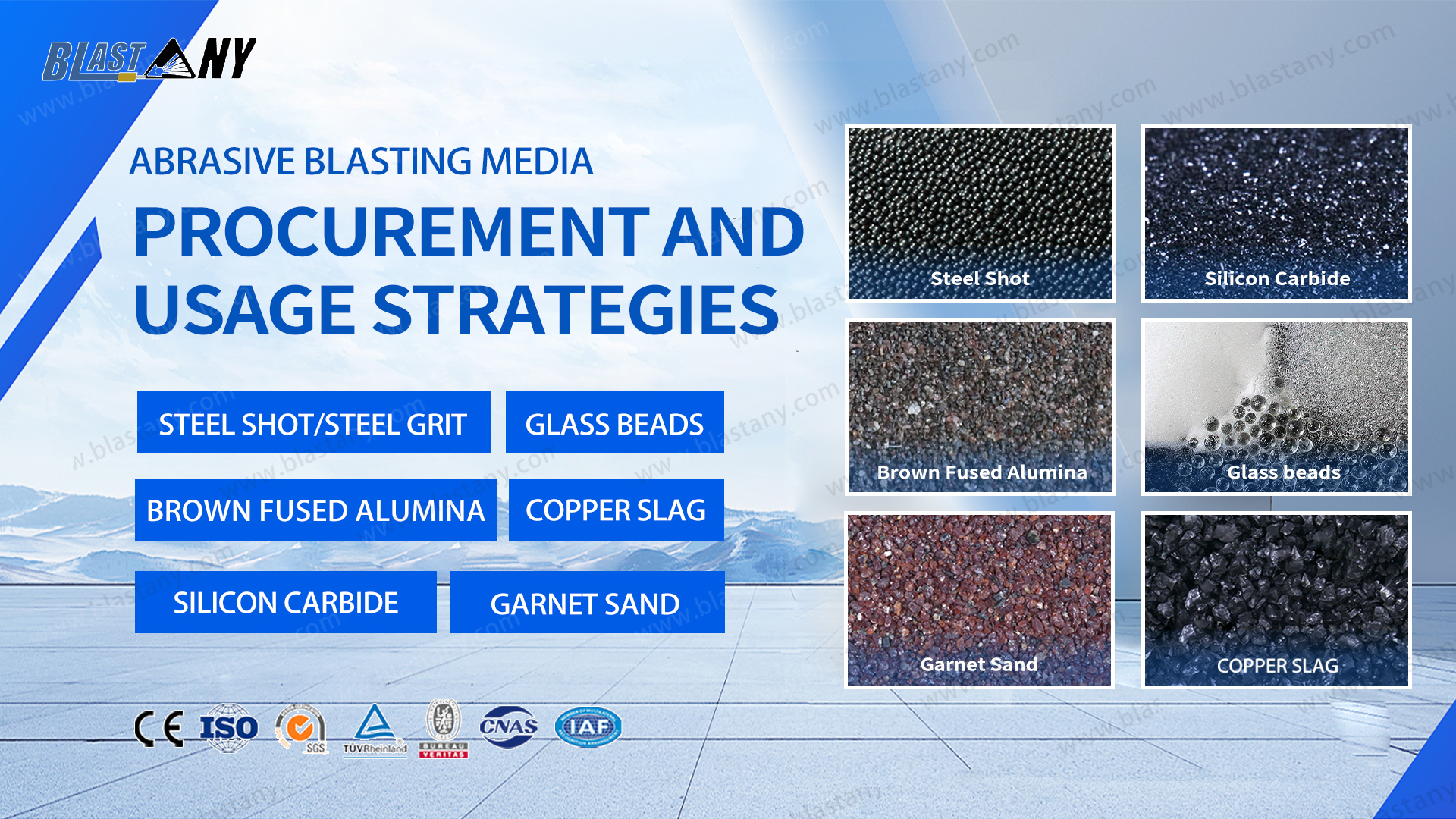

Rising Costs of Abrasive Blasting Media: How Can Enterprises Optimize Procurement and Usage Strategies?

In recent years, the continuous price increase of abrasive blasting media has imposed significant cost pressures on industries such as manufacturing, ship repair, and steel structure treatment. To address this challenge, enterprises must optimize both procurement and usage strategies to reduce co...Read more

-

Phone

-

E-mail