The sandblasting cleaning technology for the inner walls of pipelines utilizes the compressed air or a high-power motor to drive spray blades at high rotational speeds. This mechanism propels abrasive materials such as steel grit, steel shot, and garnet sand against the surface of the steel pipe under centrifugal force. The process effectively removes rust, oxides, and contaminants while achieving the desired uniform roughness on the pipe surface due to the intense impact and friction exerted by the abrasives. Following sandblasting rust removal, there is not only an enhancement in the physical adsorption capacity of the pipe surface but also an improvement in mechanical adhesion between the anti-corrosion coating and the pipeline surface. Consequently, sandblasting is considered an optimal method for rust removal in pipeline anti-corrosion applications.

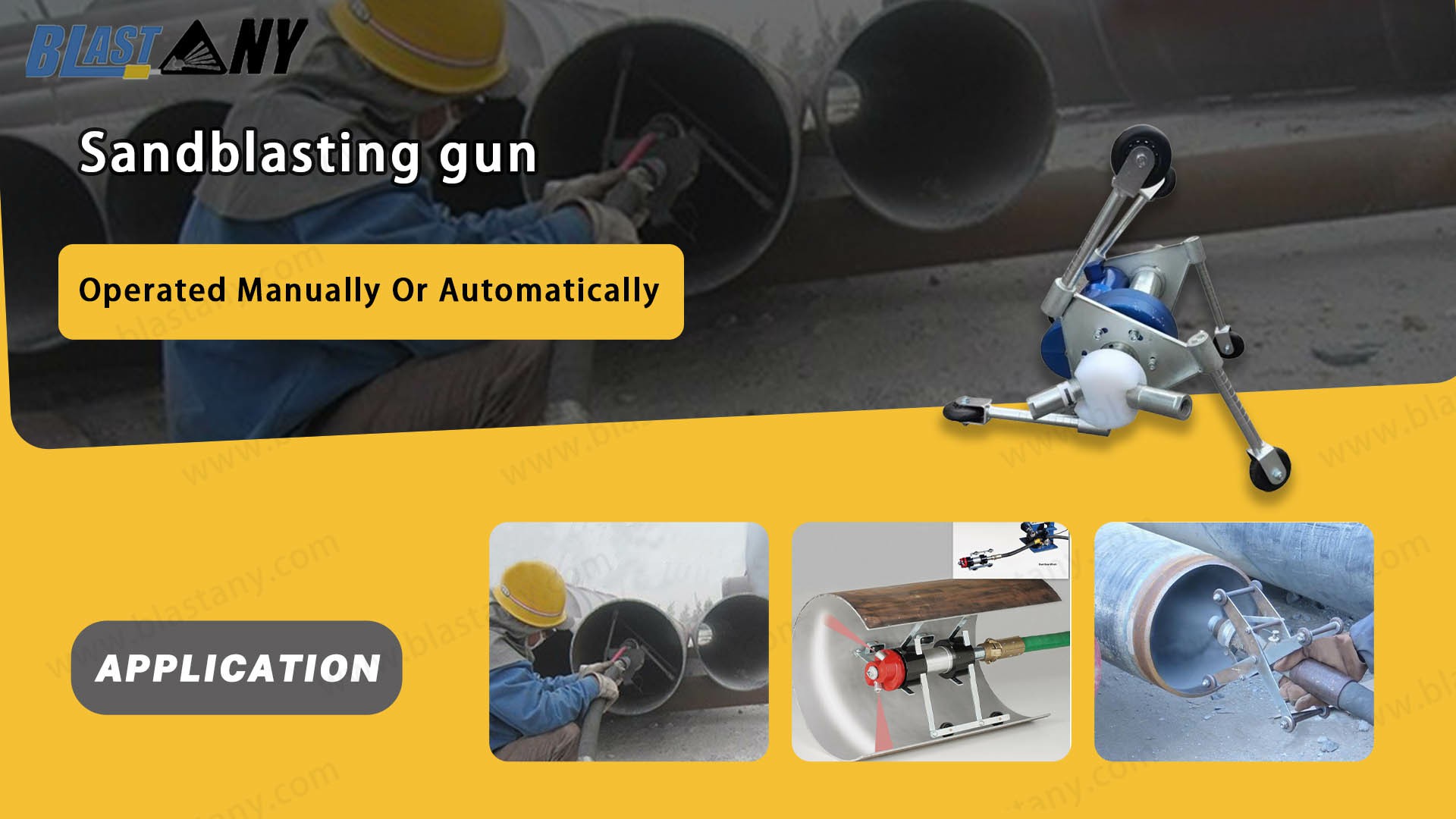

Blastany offers two models of internal pipe sandblasting guns: JD SG4-1 and JD SG4-4, designed for cleaning pipes with varying diameters. The JD SG4-1 model accommodates pipe diameters ranging from 300 to 900 mm and features a Y-shaped nozzle that can be connected to a sandblasting tank or air compressor for effective internal cleaning. Under high pressure, abrasives are ejected in a fan pattern, facilitating efficient rust and paint removal. Conversely, JD SG4-4 is suitable for smaller pipes with diameters from 60 to 250 mm (extendable up to 300 mm) and allows for 360-degree spraying when connected to a sandblasting tank or air compressor, thereby enhancing its cleaning efficacy.

Post time: Feb-28-2025