Non-metallic abrasives play a vital role in industrial surface treatment and cutting operations, mainly including materials such as garnet sand, quartz sand, glass beads, corundum and walnut shells etc. These abrasives process or cut workpiece surfaces through high-speed impact or friction, with their working principle primarily based on kinetic energy conversion and micro-cutting mechanisms.

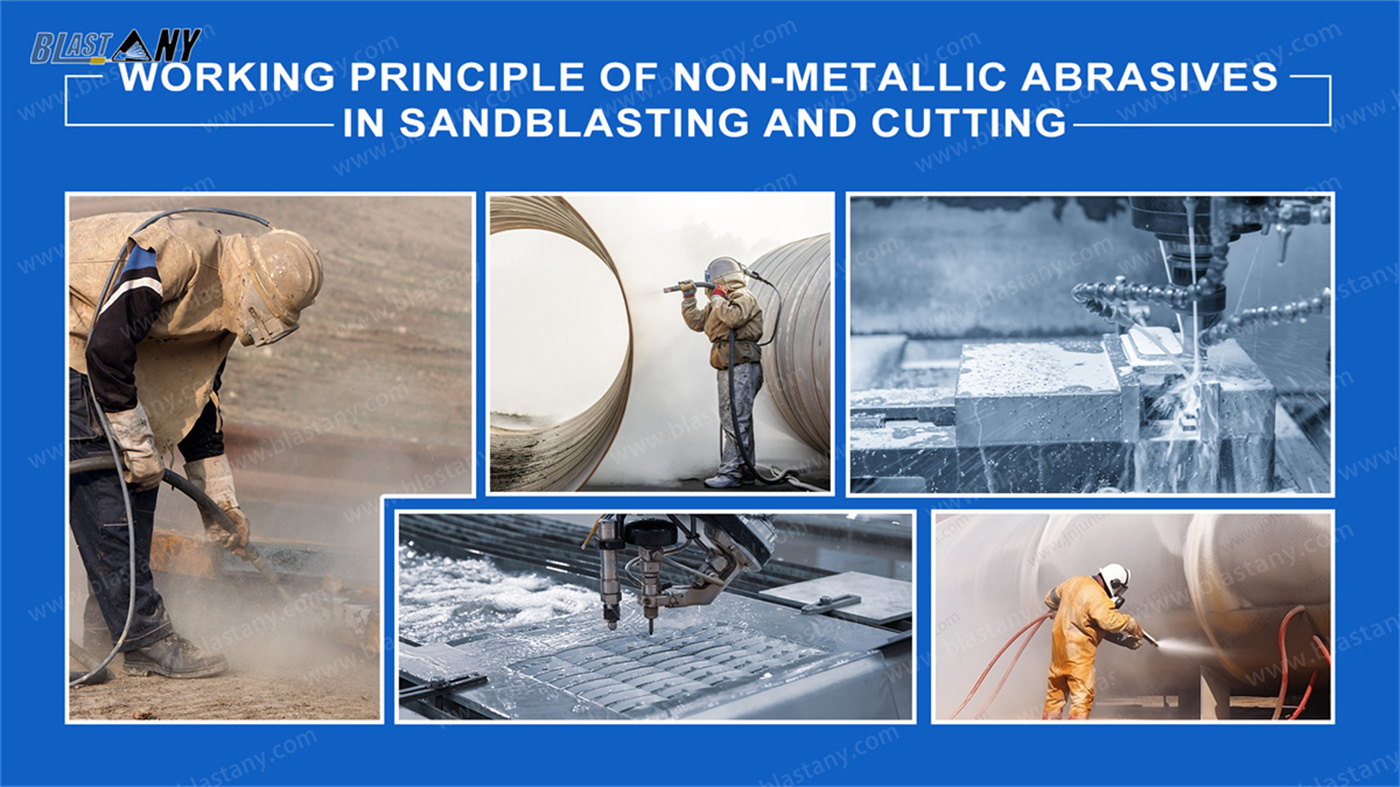

In sandblasting operations, non-metallic abrasives are accelerated by compressed air or centrifugal force to form a high-speed particle stream that impacts the workpiece surface. When abrasive particles strike the material surface at high velocity, their kinetic energy is converted into impact force, causing micro-cracks and removal of surface material. This process effectively eliminates rust, oxide layers, old coatings, and other contaminants while creating a uniform roughness that enhances adhesion for subsequent coatings. Different hardness levels and particle sizes of abrasives allow for varying treatment effects, ranging from light cleaning to deep etching.

In cutting applications, non-metallic abrasives are typically mixed with water to form an abrasive slurry, which is then ejected through a high-pressure nozzle. The high-speed abrasive particles generate micro-cutting effects at the material's edge, with countless small material removals accumulating to achieve macroscopic cutting. This method is particularly suitable for cutting hard and brittle materials such as glass and ceramics, offering advantages like minimal heat-affected zones, high cutting precision, and absence of mechanical stress.

The selection of non-metallic abrasives requires comprehensive consideration of material hardness, particle shape, size distribution, and other factors. Different applications demand optimized abrasive parameters to achieve the best processing results and cost efficiency.

For more information, please feel free to discuss with our company!

Post time: May-14-2025