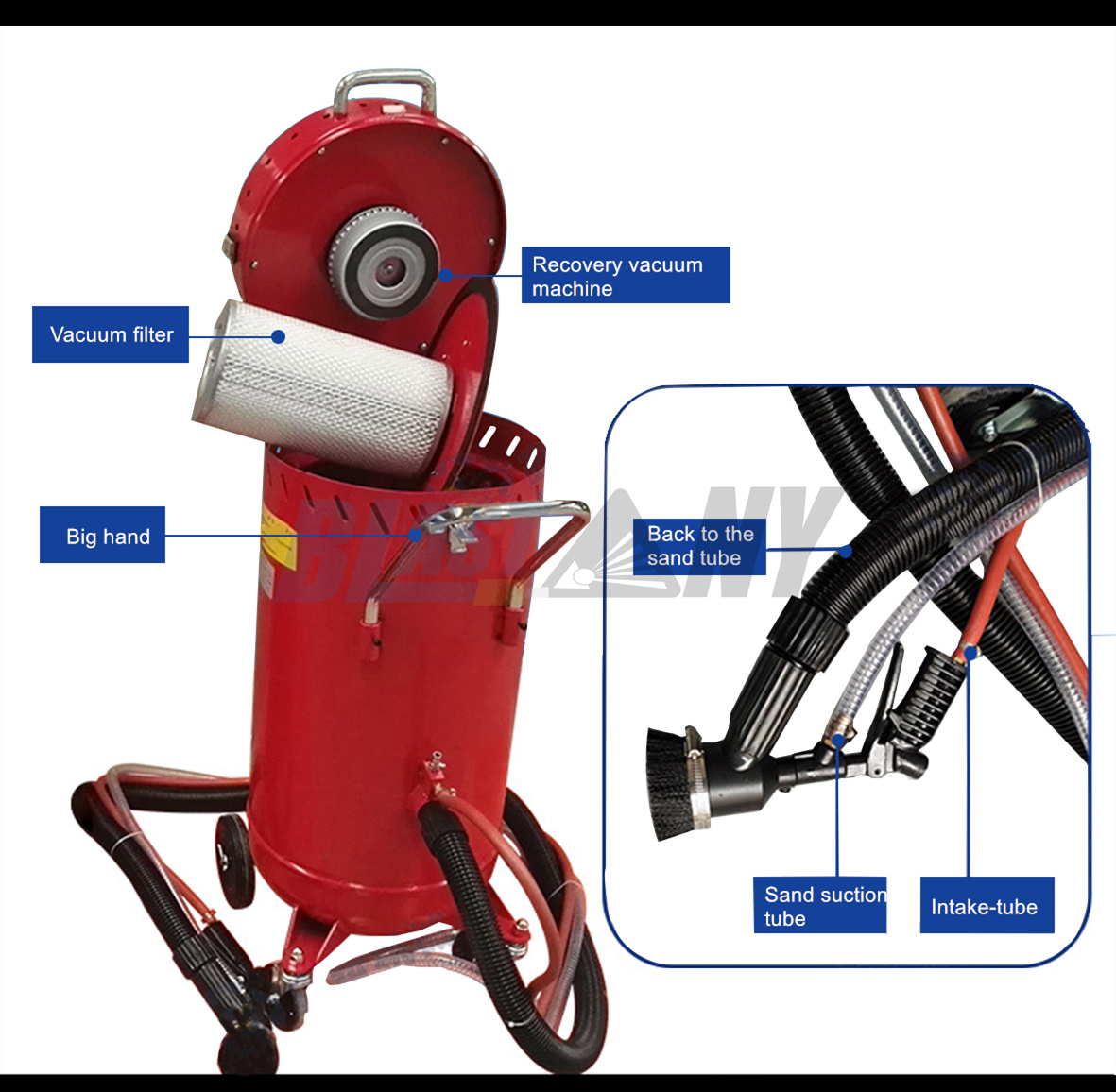

28 gallon abrasive automatic recovery cycle sandblaster

Product Description

Junda JD400DA-28 gallon sandblasting pot, built-in vacuum abrasive recovery system, Can use conventional abrasives such as garnet sand, brown corundum, glass beads, etc,built-in recovery vacuum motor and dust filter, can recycle abrasive。

Application Field

1, movable sand storage tank, rear wheel convenient transportation.

2, built-in recovery vacuum motor and vacuum filter element

3, can recycle abrasive, reduce the cost of rust removal.

Product Application

Is mainly used for all kinds of steel plate rust removal, steel structure rust removal, ship refurbishment, automobile refurbishment, anti-corrosion engineering, oil pipeline anti-rust removal, shipyard rust removal, engineering vehicles

Refurbishment, mechanical equipment refurbishment, metal mold surface sandblasting.

Operation instructions and Precautions

1. If the protected brush transmission device is not in the proper position, put it right now.

2. Set the air compressor to 8 kg force/square centimeter.

(More or less, depending on the surface to be treated)

3. Connect the air pipe connector to the air inlet connector located on the handle.

4. Connect the power cable to the power supply.

5. Aim the gun at the surface to be cleaned and turn the switch on the top of the vacuum machine to the open position.

6,

Hold the gun in one hand and the brush handle in the other. Note: Do not apply pressure by pointing the brush at the treated surface! The function of the brush is only to prevent the waste of sand, and then for grinding

The material is kept in a sealed vacuum cycle to achieve recirculation. Brushes are not expected to play an auxiliary role in abrasion processing.

7. Both hands should move in the direction of the rust removal or pre-painted working surface.

8. You can vary the size of the jet by extending or shortening the nozzle with a lock nut.

9, hard brush can be used for plane, can also be used for Angle, corner. Before you start, spread the bristles out so they don't cover the spray holes in the brush.

(Abrasives wear down the bristles)

. On the edge of the car door, we suggest that you wrap stiff hair around the edge of the door for good vacuum environment and good coverage.

10. After each work, remove the vacuum brush and flick off the dust on the filter element. After one hour of continuous work, remove the vacuum brush and use DC air or vacuum cleaner

Blow off the dust.

11. When spraying at a 90 degree Angle, adjust the gun at a 45 degree Angle to reach the deep position. Move the spray gun slowly in a circular motion to achieve the effect. After sandblasting, loosen the two clamps and empty

Dust collecting filter element and storing abrasive in a dry way.

TECHNICAL FILE

(All photos here are for reference only,The text description shall prevail.)

|

Junda 28 gallon automatic recycling sandblasting pot |

|

|

Model |

JD400DA |

|

Dimensions |

1100×400×420mm |

|

Tank size |

380 x 1040 mm in diameter |

|

Sand blasting pressure |

0.6-0.8Mpa |

|

Supporting air compressor |

7.5 KW and above |

|

Sandblasting pipe |

3m |

|

Capacity |

100 liters /28 gallons |

|

Loading amount of sand |

25KG |

|

Recycling machine |

1200W |

|

Inlet ball valve port |

1 piece |

|

Vacuum filter |

1 piece |

|

Rubber wheel |

1 piece |

|

Abrasive use |

36-320# |

|

Sand-blasting gun |

1 Automatic return sandblast gun |

|

Sand suction tube |

1 piece |

|

Weight |

40KG |

|

Matters need attention |

1. Personal protection should be done before work. 2. Do not use working pressure higher than permitted. 3. Use clean abrasives to prevent blockage of spray guns. 4. The air pressure in the tank should be unloaded to zero after the work is finished |

application area

Products categories