Copper slag is the slag produced after copper ore is smelted and extracted, also known as molten slag. The slag is processed by crushing and screening according to different uses and needs, and the specifications are expressed by the mesh number or the size of the particles.

Copper slag has high hardness, shape with diamond, low content of chloride ions, little dust during sandblasting, no environmental pollution, improve the working conditions of sandblasting workers, rust removal effect is better than other rust removal sand, because it can be reused, economic benefits are also very considerable, 10 years, the repair plant, shipyard and large steel structure projects are using copper ore as rust removal.

When quick and effective spray painting is needed, copper slagis the ideal choice.

Steel slag processing process is for the sake of separatingdifferent elements from the slag. It involves the process of separation, crushing, screening, magnetic separation, and air separation of the slag generated during the steel smelting process. The iron, silicon, aluminum, magnesium, and other elements contained in the slag are separated, processed, and reused to greatly reduce environmental pollution and achieve effective utilization of resources.

The surface finish of the workpiece after steel slag treatment is above Sa2.5 level, and the surface roughness is above 40 μm, which is enough to meet the general industrial coating needs. At the same time, the surface finish and roughness of the workpiece are related to the particle size of the steel slag and increase with the increase of the particle size. Steel slag has certain crushing resistance and can be recycled.

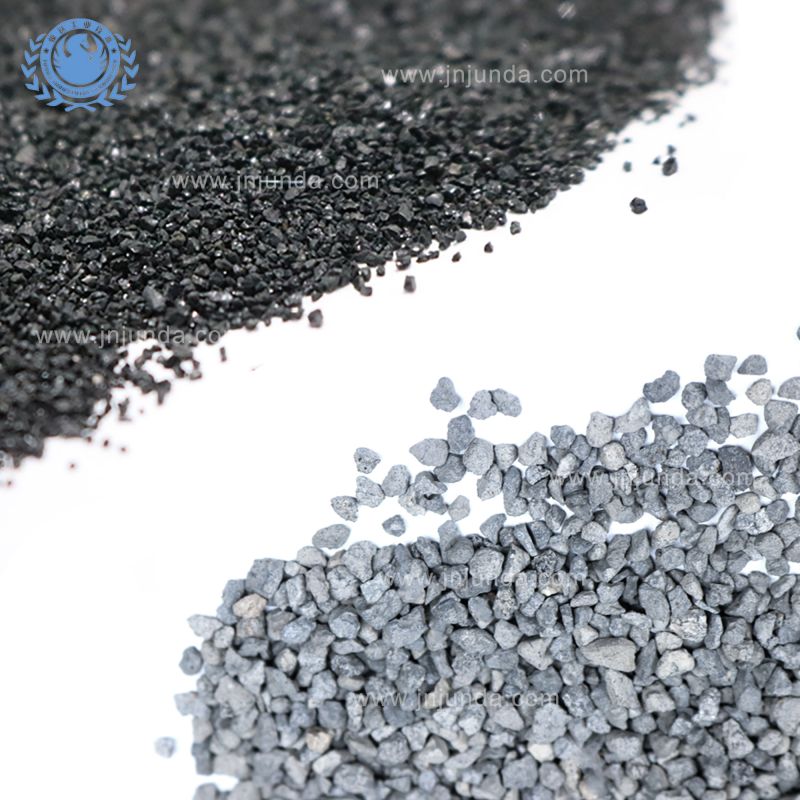

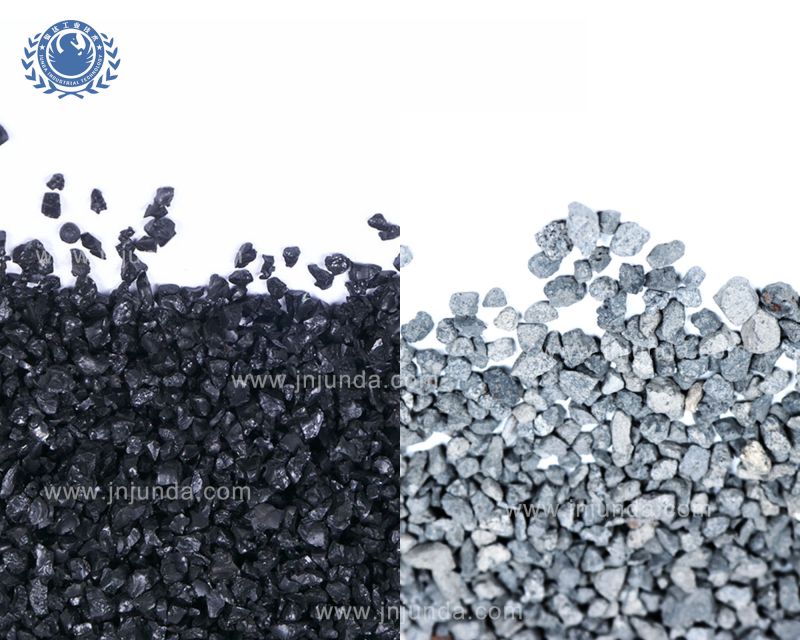

Effect contrast:

1.Observing the surface finish of samples treated with different grinding materials, it is found that the surface of the workpiece treated with copper slag is brighter than that of steel slag.

2.The roughness of the workpiece treated with copper slag is larger than that of steel slag, mainly for the following reasons: copper slag has sharper edges and angles, and the cutting effect is stronger than that of steel slag, which is easier to improve the roughness of the workpiece

Post time: Mar-21-2024