Welcome to our websites!

News

-

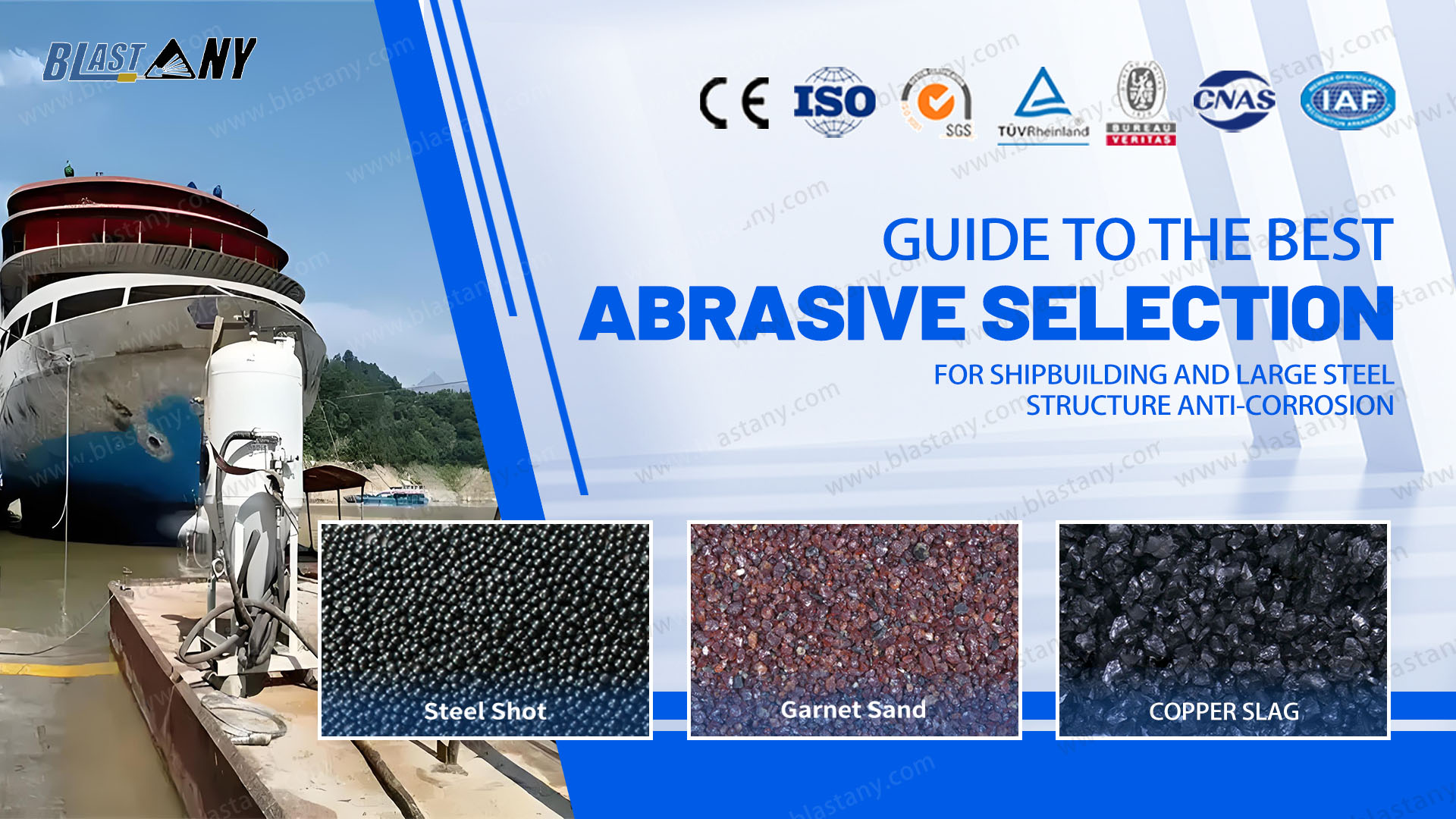

Guide to the best abrasive selection for shipbuilding and large steel structure anti-corrosion projects

In shipbuilding and large steel structure anti-corrosion projects, the selection of abrasives needs to be combined with factors such as rust removal efficiency, surface quality, environmental protection and cost. The advantages and applicable scenarios of different abrasives are significantly dif...Read more -

Selection and Requirements of Sandblasting Equipment for Offshore Oil Production Platforms

The selection of sandblasting equipment for offshore oil production platforms demands a comprehensive consideration of environmental peculiarities, safety, efficiency, and durability. The following are the key aspects: 一. Equipment Selection Requirements 1. Explosion – proof Design It is...Read more -

How to select abrasives in low carbon era

Selecting the right abrasive for surface blasting depends on the material being blasted, the desired finish, and environmental considerations. Key factors include hardness, density, shape, and size of the abrasive, as well as the abrasive’s ability to create the desired surface profile. En...Read more -

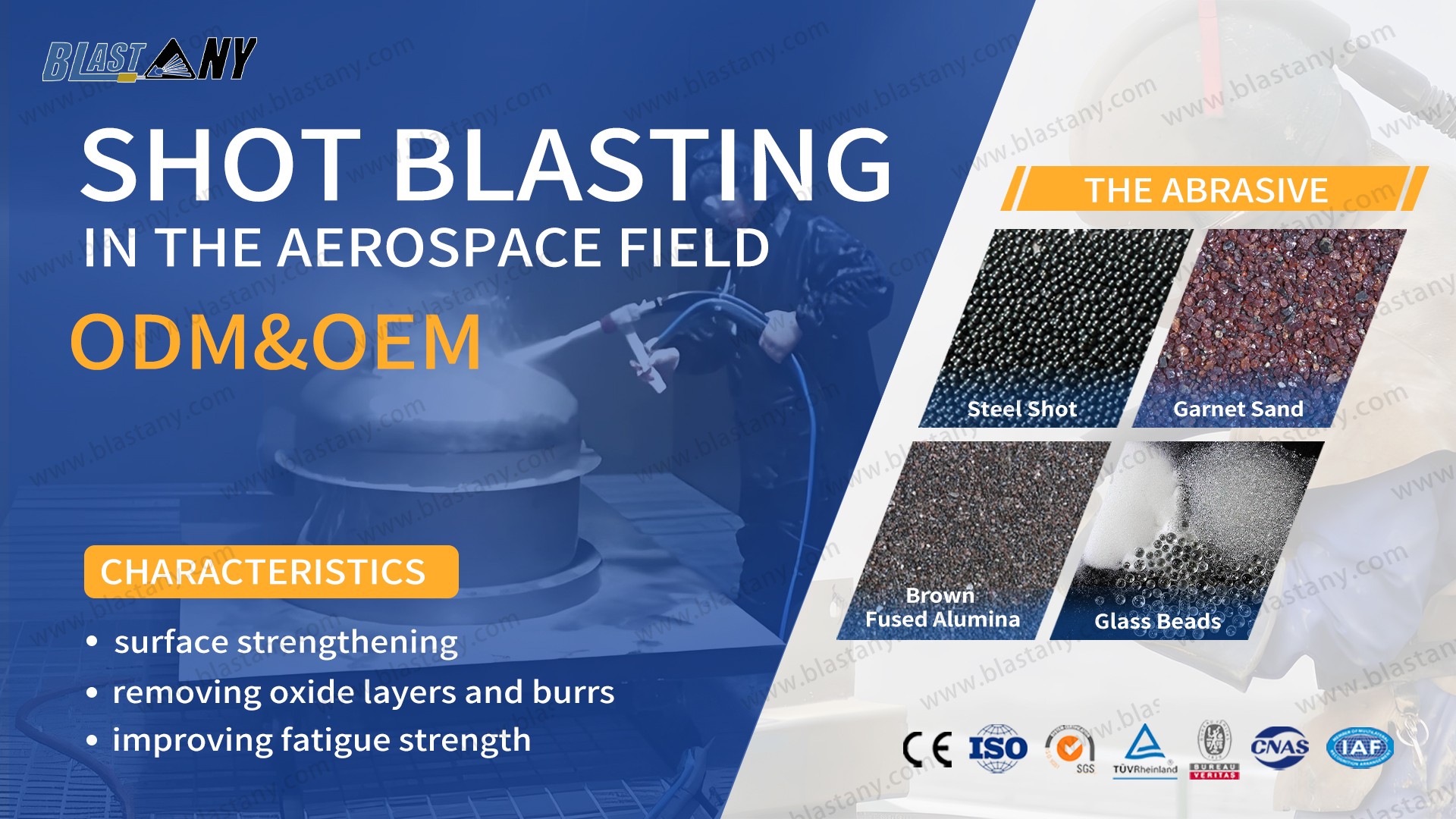

Characteristics and requirements of shot blasting in the aerospace field

Shot blasting in the aerospace field has the characteristics of surface strengthening, removing oxide layers and burrs, and improving fatigue strength, and has strict requirements on shot type, processing parameters, surface quality, etc. The main features and requirements of shot blasting in th...Read more -

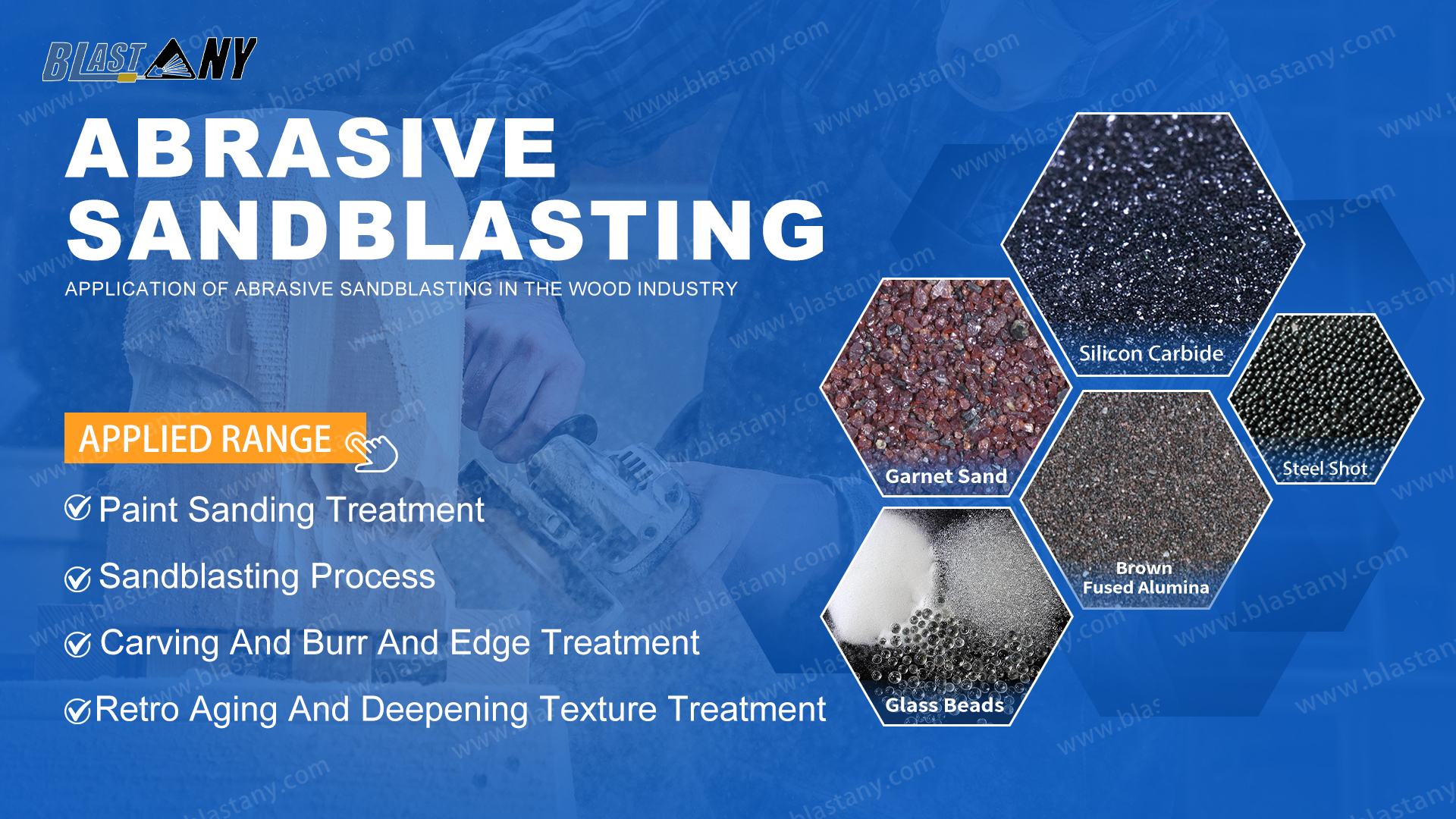

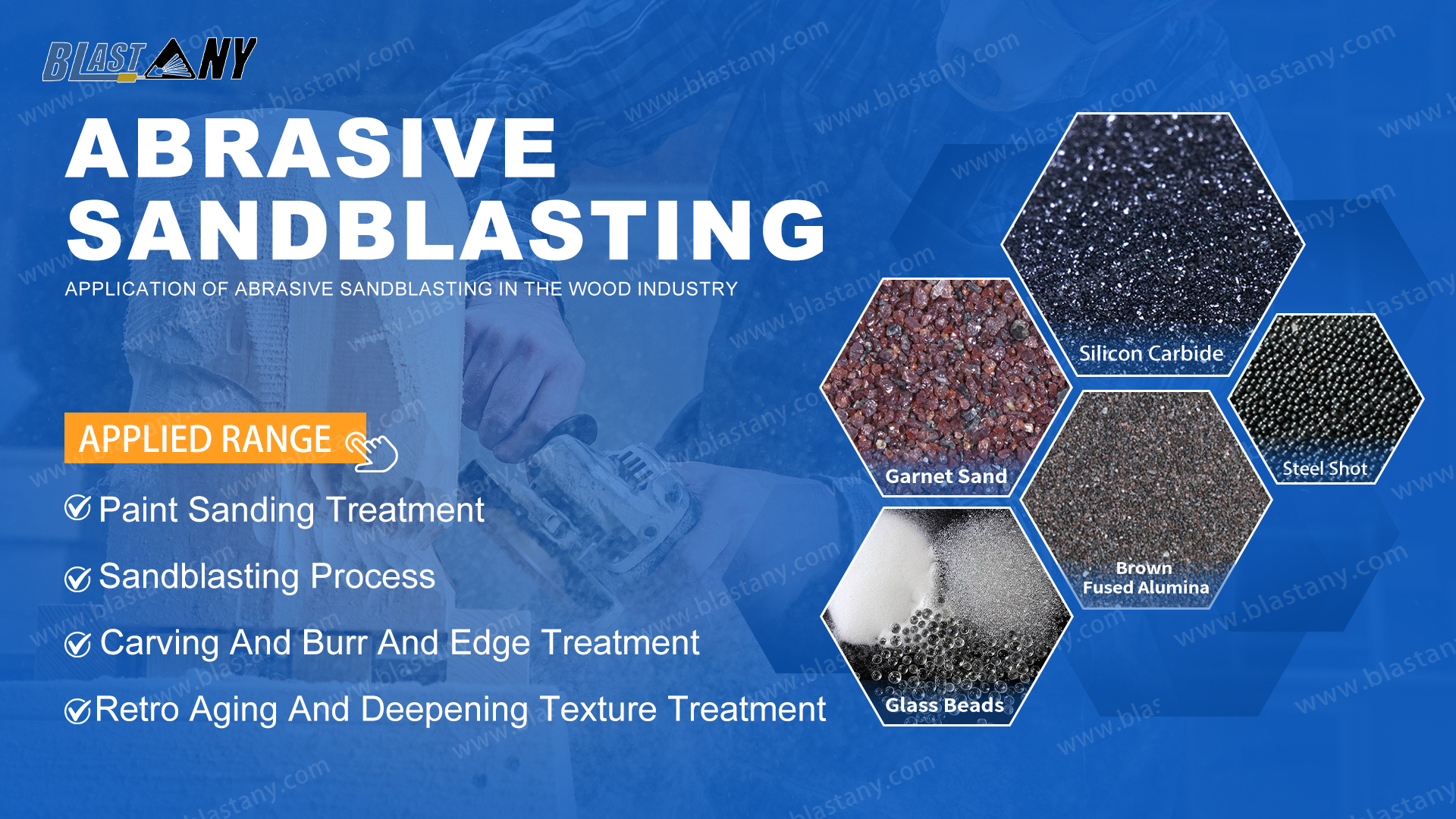

Application of abrasive sandblasting in the wood industry

The wood sandblasting process can be widely used in the processing of wood surface and burr cleaning after carving, paint sanding, wood antique aging, furniture renovation, wood carving and other processes. It is used to improve the aesthetics of the wood surface, deep processing of wooden crafts...Read more -

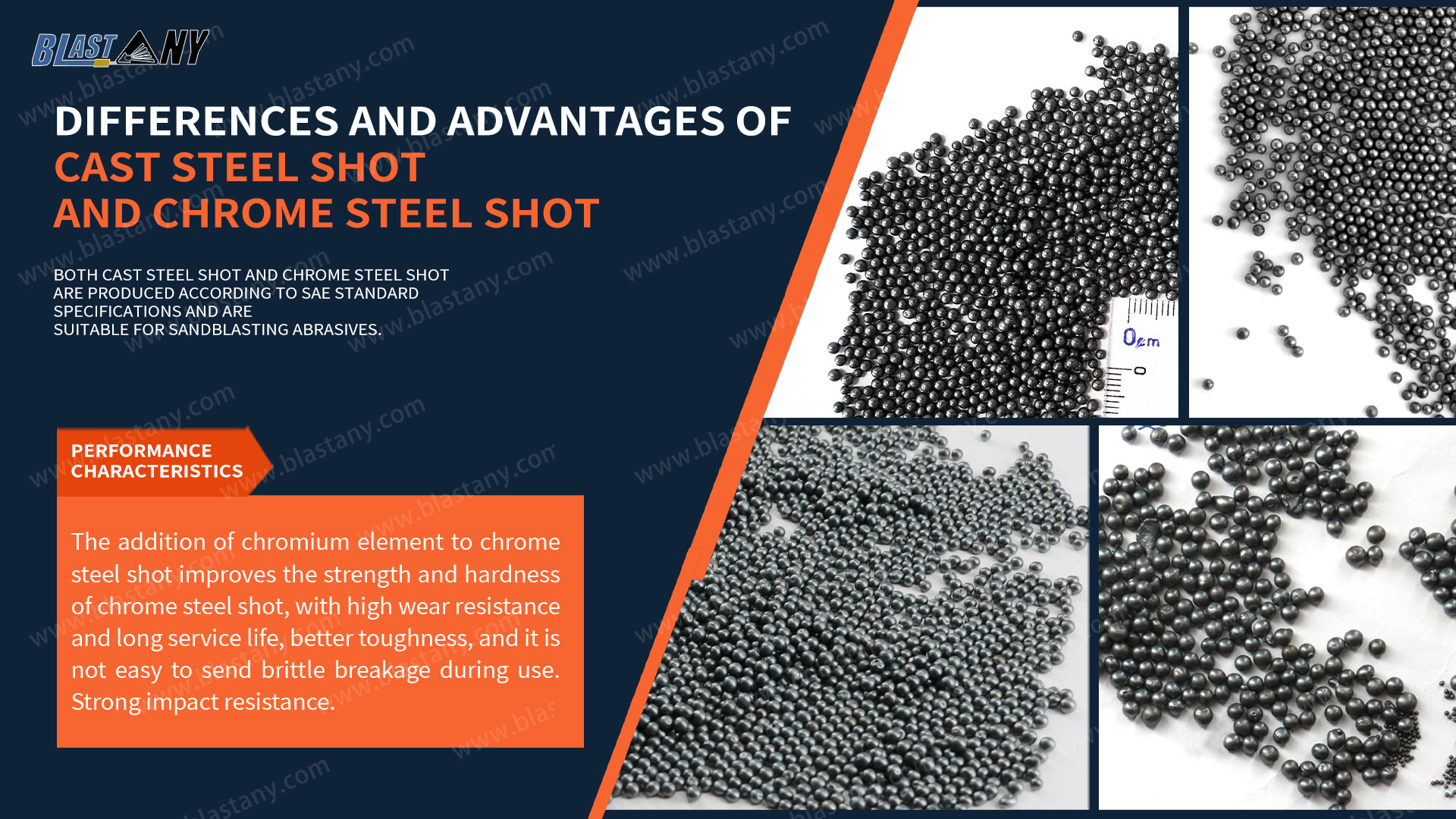

Differences and advantages of cast steel shot and chrome steel shot

Differences and advantages of cast steel shot and chrome steel shot: Both cast steel shot and chrome steel shot are produced according to SAE standard specifications and are suitable for sandblasting abrasives. Difference: Chrome steel shot is our patented product, and we are the only manufactur...Read more -

Stone sandblasting: from technology to innovation

As we all know, sandblasting has a wide range of applications, involving all walks of life. Today we mainly introduce its application in stone. 1. What is stone sandblasting Stone sandblasting is to spray sandblasting abrasives at high speed onto the surface of stone through high-pressure airflo...Read more -

Properties and Applications of Grinding Rods and Steel Cylpebs

Characteristics and Applications of Grinding rods and Steel Cylpebs Grinding rods are formed by pressure and have a well-aligned grain structure that can better withstand warping and wear. It is a common form of steel, usually a long strip of steel with a cross-section of round, square, hexagonal...Read more -

Father’s Day

Fatherly love is supreme, great and glorious. Fight against the years, fight against time, hope that time will be gentle, and every father can grow old slowly. Father’s Day is coming. Wish every father a happy Father’s Day! With the warmest wishes!Read more -

Principle of Sandblasting with Garnet Sand and Steel Grit

Garnet sand and steel grit are widely used in the sandblasting field to clean the workpiece surface and improve its surface roughness. Do you know how they work? Working principle: Garnet sand and steel grit, with compressed air as power (the output pressure of air compressors is between 0.5 and...Read more -

Working Principle of Non-Metallic Abrasives in Sandblasting and Cutting

Non-metallic abrasives play a vital role in industrial surface treatment and cutting operations, mainly including materials such as garnet sand, quartz sand, glass beads, corundum and walnut shells etc. These abrasives process or cut workpiece surfaces through high-speed...Read more -

Portable automatic recycling sandblasting pot

As we all know, in the field of metal surface treatment, sandblasting pots occupy a very important place. Sandblasting pots are a kind of equipment that uses compressed air to spray abrasives at high speed onto the surface of the work piece for cleaning, strengt...Read more

-

Phone

-

E-mail