Our Sandblasting machine is widely used in ship building, mining, machinery, oil pipelines, machine tools, metallurgy, boiler,machinery manufacturing, port construction, water conservancy projects such as surface derusting, smooth surface.It is the most widely used product of abrasive jet, and the sandblasting machine is generally divided into many types: Pressurized sandblasting machine,vacuum abrasive recovery sandblasting machine etc.

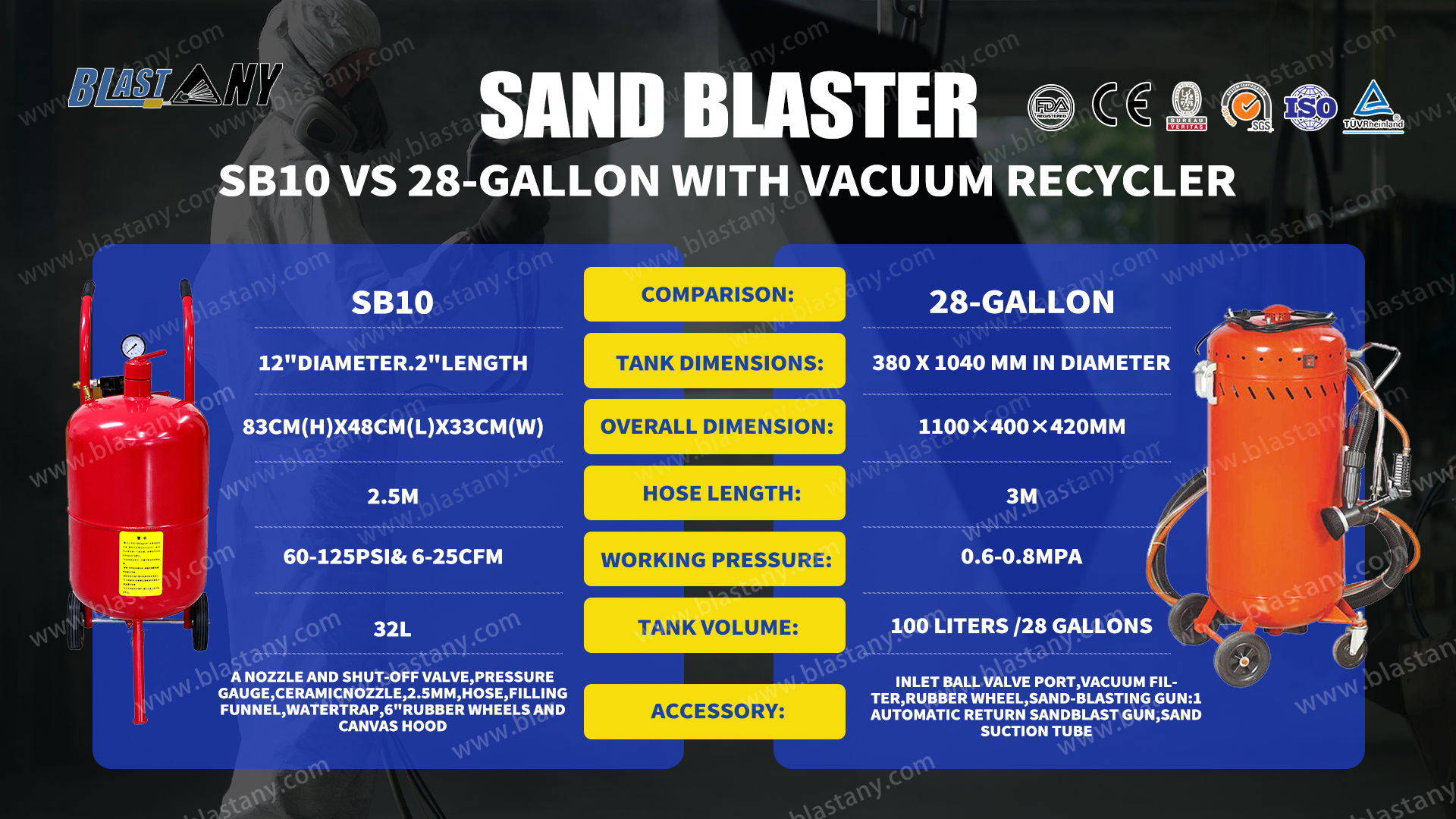

1. The comparison of SB10&28gallon’sspecification;

| Comparison: | SB10 |

28Gallon |

| Tank Dimensions: | 12″Diameter.2″Length | 380 x 1040 mm in diameter |

| Overall dimension: | 83cm(H)x48cm(L)x33cm(W) | 1100×400×420mm |

| Hose length: | 2.5M | 3m |

| Working pressure: | 60-125PSI& 6-25CFM | 0.6-0.8Mpa |

| Tank volume: | 32L | 100 liters /28 gallons |

| Accessory: | a nozzle and shut-off valve,pressure gauge,ceramicnozzle,2.5mm,hose,filling funnel,watertrap,6″rubber wheels and canvas hood | Inlet ball valve port,Vacuum filter,Rubber wheel,Sand-blasting gun:1 Automatic return sandblast gun,Sand suction tube |

2.The comparison of SB10&28gallon’s effeciency;

SB10:

Pressurized desian 30% more sandblasting power than siphon units

Provides more abrasive when you need truly efficient performance

JD400DA-28 gallon sandblasting pot, with built-in vacuum abrasive recovery system, which can use conventional abrasives such as garnet sand, brown corundum, glass beads, etc, and the built-in recovery vacuum motor and dust filter can recycle and improve the efficiency of using the abrasive.

3.The advantages of 28gallon sandblasting pot;

Product feature:

1, movable sand storage tank, rear wheel is convenient for transportation.

2, built-in recovery vacuum motor and vacuum filter element

3, can recycle abrasive, reduce the cost of rust removal.

For more information, please feel free to discuss with our company!

Post time: Oct-23-2025