Junda Sandblasting machine in the use process, in order to ensure the correct use of the stable use of efficiency, it is very important to understand the work of the equipment in detail and where, so, in order to help users understand the use of equipment in more detail, the following is introduced on its working principle diagram.

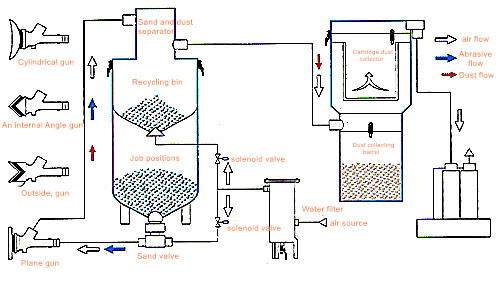

Sandblasting machine is generally divided into dry sandblasting machine and liquid sandblasting machine two categories, dry sandblasting machine and can be divided into suction sandblasting machine and road type sandblasting machine two types of sandblasting machine is also called sandblasting machine, shot peening machine suction dry sandblasting machine. Generally, a complete suction dry sand blasting machine is generally composed of six systems, namely, structural system, medium power system, pipeline system, dust removal system, control system and auxiliary system.

Suction dry sand blasting machine is powered by compressed air, through the high speed movement of air flow in the negative pressure formed in the spray gun, the abrasive through the sand pipe. Suction spray gun and through the nozzle injection, spray to be processed surface, to achieve the desired processing purpose. A complete dry sandblasting machine work unit is generally composed of four systems, namely pressure tank, medium power system, pipeline system and control system. Working principle of press-in dry sand blasting machine: press-in dry sand blasting machine is powered by compressed air. Through the working pressure established by the compressed air in the pressure tank, the abrasive passes the sand valve, is pressed into the sand pipe and is shot through the nozzle, and is sprayed to the processed surface to reach the expected processing objectives.

Post time: Nov-25-2021