Welcome to our websites!

News

-

Sand blasting machine to solve the problem

Junda Sand blasting machine, like most equipment, will certainly have failure in the use of the process, but in order to better solve this problem, to ensure the smooth operation of the equipment, it is necessary to understand the failure of the equipment and the solution, which is conducive to t...Read more -

Influence of steel shot & grit selection on blasting strength

The steel shot and grit in the shot blasting machine continuously impact the workpiece during the blasting process ,to remove the oxide scale, casting sand, rust, etc. It must also have excellent impact toughness. That is to say, the steel shot and l grit material must have a strong ability to r...Read more -

Understand the process of sand blasting machine common sense convenient operation(Ⅲ)

Stress relief and surface strengthening By hitting the surface of the workpiece with sand shot, stress is eliminated and the surface strength of the workpiece is increased, such as the surface treatment of the workpiece such as springs, machining tools and aircraft blades. Sand blasting machine c...Read more -

Understand the process of sand blasting machine common sense convenient operation(one)

Keywords: Junda sandblasting machine sandblasting cabinet Sand blasting machine in use, need to understand its process, so as to reduce equipment operation failure, promote the use of equipment efficiency, and for the convenience of more users to understand the us...Read more -

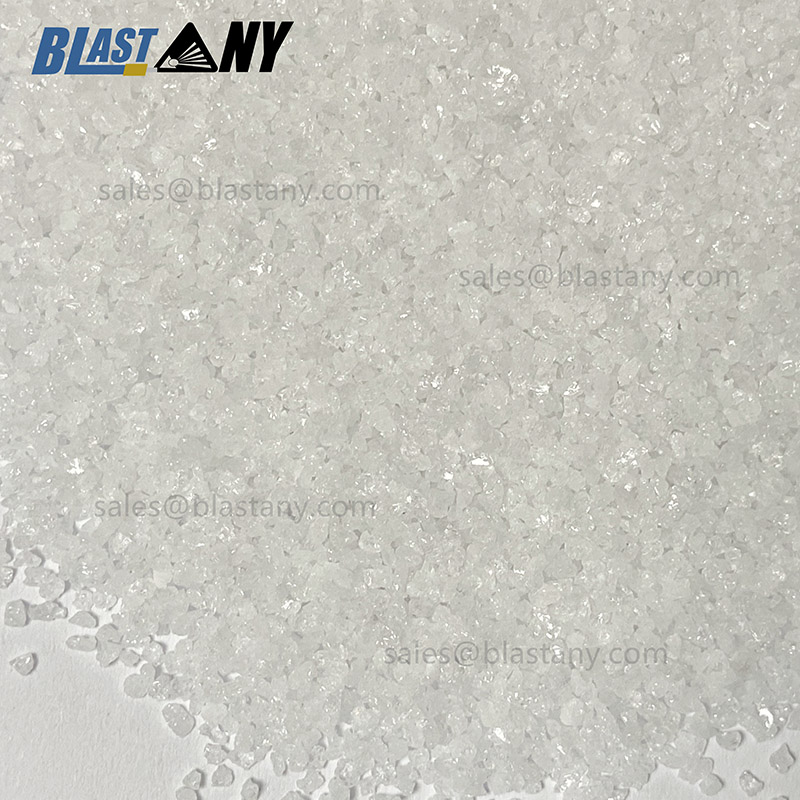

Different usages of Glass Bead

Glass beads are widely used as a new type of material in medical equipment and nylon, rubber, engineering plastics, aviation and other fields, such as fillers and reinforcing agents. Road glass beads are mainly used in normal temperature and hot melt road marking coatings. There are two kinds o...Read more -

Junda Sand blasting machine for what types of surface processing

With the acceptance of Junda sandblasting machine by various industries, it is widely used in the surface processing of products in various industries, but there will be a lot of users can not clearly distinguish the specific application, so the following is the corresponding introduction. 1, sui...Read more -

Technical Parameter – Sandblasting Pot

Model JD-600 D/W JD-700D/W JD-800D/W JD-1000D/W Diameter 600mm 700mm 800mm 1000mm Color Customers’ Requirements Customers’ Requirements Customers’ Requirements Customers’ Requirements Blasting Media Abrasive Abrasive Abrasive Abrasive Height 1450mm 1650mm 1800m...Read more -

What kind of sand does Junda sand blasting machine choose

Sand as an important material in Junda sand blasting machine equipment, the use of its products also has certain use requirements, for example, the type of sand used in different cleaning ranges is also different, so, in order to facilitate everyone’s understanding, the next type of sand is...Read more -

How does blasting machine do moisture-proof work

In use process is easy to cause due to improper operation of automatic sandblasting machine be affected with damp be affected with damp, so in order to ensure the use efficiency of the equipment and the use of performance, can only be moistureproof equipment operation, equipment to be placed in v...Read more -

White Corundum Abrasives

White corundum abrasive, also called white aluminium oxide, has good thermal stability, high temperature resistance above 1750 degrees, high purity, good self-sharpening, strong grinding ability, low calorific value, high efficiency and acid-base corrosion resistance. It has proven itself in many...Read more -

Junda manual sand blasting machine how to suction sand operation

As we all know, Junda sandblasting machine is a kind of multi-model, multi-type equipment, manual is one of the many types of equipment, due to the majority of equipment types, users can not understand each equipment, so the next manual equipment sandblasting principle is introduced. Principle: S...Read more -

How to use Junda sand blasting machine?

1. Before use Connect to the air source and power supply of the sandblasting machine, and open the power switch on the electrical box. According to the need to adjust the pressure of compressed air through the reducing valve into the spray gun between 0.4~ 0.6mpa. Choose the suitable abrasive i...Read more

-

Phone

-

E-mail